ERP Software for Manufacturing

In the rapidly evolving world of manufacturing, staying competitive requires more than just producing quality products. Efficiently managing operations, reducing costs, and optimizing resources are equally crucial. This is where Enterprise Resource Planning (ERP) systems come into play. Specifically, ERP for manufacturing is designed to address the unique challenges faced by manufacturers, offering solutions that streamline processes and drive significant cost savings. In this blog, we’ll explore how manufacturing ERP systems, like Microsoft Business Central, can help manufacturers achieve these goals.

1. Introduction to ERP for Manufacturing

What is ERP?

Enterprise Resource Planning (ERP) is a type of software that integrates various business processes into a single unified system. It manages core business functions such as finance, human resources, supply chain, manufacturing, and customer relationship management. For manufacturers, ERP systems are vital in streamlining operations and ensuring that all parts of the business work together seamlessly.

What is Manufacturing ERP?

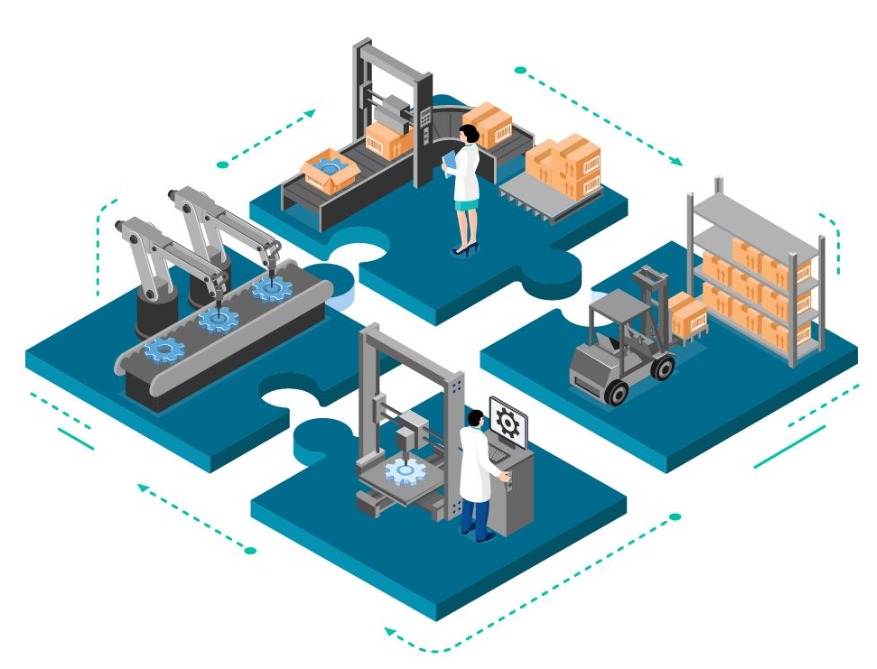

Manufacturing ERP software is a specialized type of Enterprise Resource Planning (ERP) system designed to manage and integrate all aspects of a manufacturing business. This software helps manufacturers streamline their operations, improve efficiency, and reduce costs by providing a centralized platform for managing various business processes.

Importance of ERP in Manufacturing

In the manufacturing sector, where efficiency and precision are paramount, ERP systems play a crucial role. They enable manufacturers to gain control over their production processes, reduce waste, manage inventory effectively, and improve overall productivity. As the manufacturing industry becomes more complex, the need for a robust ERP system becomes increasingly apparent.

Overview of Manufacturing ERP Systems

Manufacturing ERP systems are specifically designed to handle the complexities of manufacturing operations. They offer specialized features that support production planning, material requirements planning (MRP), shop floor control, and quality management. These systems are essential for manufacturers looking to maintain a competitive edge by optimizing their operations and reducing costs.

2. How ERP Streamlines Manufacturing Operations

Centralized Data Management

One of the primary benefits of implementing ERP for manufacturing is the ability to centralize data. By consolidating information from various departments—such as production, finance, and inventory—into a single system, manufacturers can ensure that all teams have access to accurate and up-to-date information. This eliminates data silos, reduces errors, and improves decision-making.

Improved Production Planning and Scheduling

Effective production planning is critical to meeting deadlines and maximizing output. Manufacturing ERP systems, like Microsoft Dynamic 365 Business Central, offer advanced planning and scheduling tools that allow manufacturers to optimize their production processes. These tools help in forecasting demand, allocating resources, and scheduling production runs to minimize downtime and maximize efficiency.

Enhanced Inventory Management

Inventory management is a significant challenge in manufacturing. Overstocking ties up capital, while understocking can halt production. An ERP system provides real-time visibility into inventory levels, helping manufacturers maintain the right balance. This ensures that materials are available when needed, reducing carrying costs and preventing production delays.

Better Supply Chain Coordination

Supply chain management is another area where ERP systems excel. Manufacturing ERP systems enable better coordination with suppliers, ensuring that materials are delivered on time and at the right cost. This reduces lead times, minimizes disruptions, and helps manufacturers respond quickly to changes in demand.

Quality Control and Compliance Management

Maintaining high-quality standards is essential in manufacturing. ERP systems help enforce quality control measures throughout the production process. They also ensure compliance with industry regulations by providing detailed documentation and traceability of products. This not only improves product quality but also reduces the risk of costly recalls or legal issues.

3. Reducing Costs with Manufacturing ERP

Minimizing Waste and Optimizing Resources

ERP systems help manufacturers identify areas where resources are being wasted. By analyzing production processes, ERP software can highlight inefficiencies and suggest improvements. This leads to better resource utilization, reduced waste, and ultimately lower production costs.

Reducing Operational Downtime

Unplanned downtime can be costly for manufacturers. ERP systems help in predictive maintenance by monitoring equipment performance and scheduling maintenance before issues arise. This proactive approach reduces the risk of equipment failure, minimizes downtime, and keeps production running smoothly.

Lowering Inventory Holding Costs

Carrying too much inventory can be expensive, tying up capital and increasing storage costs. An ERP system optimizes inventory levels by providing accurate demand forecasts and real-time inventory data. This reduces the need for excess inventory, lowers holding costs, and frees up capital for other investments.

Enhancing Financial Management and Cost Tracking

Manufacturing ERP systems offer powerful financial management tools that provide real-time insights into costs and revenues. This allows manufacturers to track expenses, manage budgets, and identify areas where costs can be reduced. Better financial management leads to improved profitability and a stronger bottom line.

4. Why Choose Microsoft Dynamic 365 Business Central for Manufacturing ERP

Seamless Integration with Existing Microsoft Tools

Microsoft Dynamic 365 Business Central is a robust ERP solution that integrates seamlessly with other Microsoft products like Office 365 and Power BI. This integration provides a unified platform for managing all aspects of manufacturing operations, from production to finance.

Scalable and Customizable to Fit Specific Manufacturing Needs

Every manufacturing business is unique, and Microsoft Dynamic 365 Business Central offers the flexibility to customize the system to meet specific needs. It’s scalable, meaning it can grow with your business, whether you’re a small manufacturer or a large enterprise.

Real-Time Insights and Analytics

With Microsoft Business Central, manufacturers can access real-time data and analytics, enabling informed decision-making. The system’s powerful reporting tools provide insights into key performance indicators, helping manufacturers optimize operations and reduce costs.

Case Studies and Success Stories

Many manufacturers have successfully implemented Microsoft Business Central to streamline their operations and reduce costs. Case studies highlight how businesses have improved efficiency, reduced waste, and increased profitability by adopting this ERP solution.

5. Conclusion

Implementing an ERP for manufacturing is a strategic move that can streamline operations, reduce costs, and improve overall efficiency. Microsoft Dynamic 365 Business Central offers a comprehensive solution tailored to the needs of manufacturers, providing the tools necessary to stay competitive in a challenging market. By adopting this powerful ERP system, manufacturers can achieve long-term success and drive growth.

If you’re ready to take your manufacturing operations to the next level, consider exploring Microsoft Dynamic 365 Business Central and see how it can transform your business.

Vatsin, a Microsoft Certified Partner, is here to implement this powerful ERP solution for you! With their expertise, you can ensure a smooth, successful transition to Business Central, tailored specifically to your business needs.