Introduction

Manufacturing in 2025 is no walk in the park. Between supply chain disruptions, rising costs, and the pressure to deliver custom orders on time, manufacturers are juggling more than ever. If you’re still relying on spreadsheets or disjointed systems to manage production, inventory, and finances, you’re not just behind the curve—you’re risking your bottom line. Enter Business Central ERP, Microsoft’s cloud-based powerhouse designed to unify your operations and drive efficiency.

But where do you begin? Getting started with Business Central ERP can feel daunting, especially for manufacturers with complex workflows. Don’t worry—this guide is your blueprint. We’ll walk you through what Business Central ERP offers, why it’s a game-changer for the manufacturing industry, and how to hit the ground running. Whether you’re a small shop or a mid-sized plant, you’ll discover actionable steps to transform your processes and boost profitability. Ready to ditch the chaos and embrace smart manufacturing? Let’s dive in.

What is Business Central ERP?

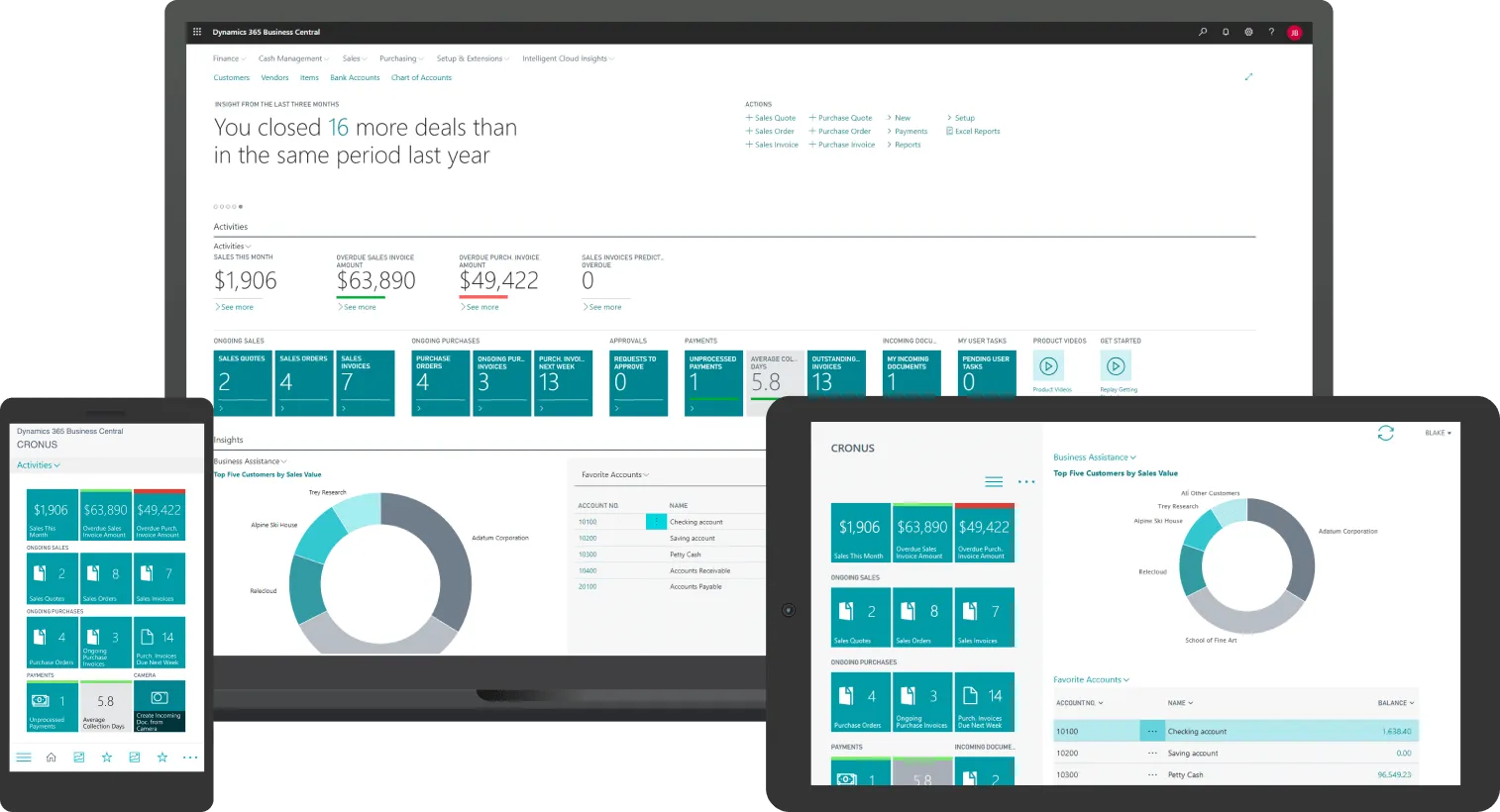

Business Central ERP, part of Microsoft Dynamics 365, is an all-in-one business management solution built for small to mid-sized manufacturers. It’s more than just software—it’s a centralized hub that connects your shop floor to your top floor, streamlining everything from production scheduling to financial reporting.

A Snapshot of Business Central ERP for Manufacturing

Think of Business Central ERP as your manufacturing command center. It integrates core processes—inventory management, production planning, supply chain tracking, and more—into a single, cloud-based platform. Born from Dynamics NAV, it’s evolved into a scalable, user-friendly ERP tailored for modern manufacturers. With real-time data and Microsoft integrations like Power BI, Business Central ERP empowers you to make informed decisions fast.

Why Manufacturers Choose Business Central ERP

What sets Business Central ERP apart? It’s purpose-built for agility. Its cloud-first design cuts hardware costs, while its manufacturing module tackles industry-specific challenges like bills of materials (BOMs) and resource planning. For manufacturers, this means less downtime, better inventory control, and happier customers—all without breaking the bank.

Key Features of Business Central ERP for Manufacturers

Business Central ERP isn’t a one-size-fits-all tool—it’s packed with features that address manufacturing pain points head-on. Here’s what you’ll unlock when you get started.

Precision Financial Management

Managing costs is make-or-break in manufacturing. Business Central ERP delivers robust financial tools—think real-time budgeting, cost tracking, and compliance reporting. You’ll see exactly where your money’s going, from raw materials to finished goods, with seamless integration into your general ledger.

Optimized Production Planning and Scheduling

Say goodbye to production bottlenecks. Business Central ERP’s manufacturing module lets you create production orders, manage BOMs, and schedule labor and machinery with precision. Need to adjust for a rush order? Its material requirements planning (MRP) keeps your shop floor humming.

Inventory and Supply Chain Mastery

Overstocking or understocking can cripple your operation. Business Central ERP gives you full visibility into inventory levels—raw materials, work-in-progress (WIP), and finished products. Pair that with supply chain tools for order management and delivery tracking, and you’ve got a lean, mean production machine.

Seamless Microsoft Integrations

Manufacturers love efficiency, and Business Central ERP delivers with integrations like Office 365 and Power BI. Generate production reports in Excel or visualize shop floor performance with dynamic dashboards—all within the same ecosystem.

- Top Features at a Glance:

- Real-time inventory tracking

- Automated production scheduling

- Financial forecasting tools

- Cloud-based accessibility

- Top Features at a Glance:

Benefits of Business Central ERP in Manufacturing

Why invest in Business Central ERP? Because it’s not just software—it’s a competitive edge. Here’s how it transforms your manufacturing business.

Cost Savings and Scalability

Business Central ERP’s cloud model slashes upfront costs—no pricey servers or IT crews needed. Plus, it scales as you grow, whether you’re adding a new product line or expanding to multiple plants. A 2023 Forrester study found manufacturers using Business Central ERP saw a 172% ROI over three years—proof it pays off.

Real-Time Insights for Smarter Moves

Data silos kill productivity. Business Central ERP breaks them down, delivering real-time insights into production, inventory, and cash flow. Spot inefficiencies, predict demand, and make decisions that keep your operation lean and profitable.

Boosted Shop Floor Collaboration

Remote work isn’t just for offices. Business Central ERP’s cloud access lets your team—shop floor workers, managers, accountants—collaborate from anywhere. Need to tweak a production order on the fly? It’s all at your fingertips.

Steps to Get Started with Business Central ERP

Ready to implement Business Central ERP in your manufacturing business? Follow these steps to ensure a smooth launch and quick wins.

Step 1: Assess Your Manufacturing Needs

Start by mapping your current processes—production workflows, inventory pain points, financial gaps. What’s working? What’s not? This baseline helps you tailor Business Central ERP to your unique setup, whether you’re in discrete manufacturing or process-based production.

Step 2: Partner with a Microsoft Expert

Don’t go it alone. A certified Microsoft partner can guide you through Business Central ERP setup, from licensing to customization. They’ll ensure your manufacturing module aligns with your BOMs, scheduling, and supply chain needs.

Step 3: Migrate Data with Care

Clean, accurate data is the backbone of Business Central ERP. Audit your existing records—inventory lists, supplier details, customer orders—and migrate them systematically. Test runs prevent surprises when you go live.

Step 4: Train Your Team Early

Adoption is key. Start training your shop floor crew, accountants, and managers on Business Central ERP before launch. Focus on role-specific tasks—e.g., how to log production orders or pull inventory reports. Hands-on sessions beat slide decks every time.

Step 5: Go Live and Optimize

Launch day isn’t the finish line—it’s the starting gun. Monitor Business Central ERP’s performance, gather team feedback, and tweak as needed. Set KPIs like reduced production downtime or faster order fulfillment to track success.

- Implementation Checklist:

- Define goals (e.g., cut inventory costs by 15%)

- Assign a project lead

- Schedule data migration

- Plan training sessions

- Test before full rollout

- Implementation Checklist:

Business Central ERP vs. Other Manufacturing Solutions

How does Business Central ERP stack up against competitors? Let’s compare it to two heavy hitters.

Business Central ERP vs. SAP Business One

SAP Business One is robust but pricey, with a steeper learning curve. Business Central ERP wins on affordability and ease of use, plus tighter Microsoft integrations—crucial for manufacturers already in the Office 365 ecosystem.

Business Central ERP vs. Oracle NetSuite

NetSuite shines for large enterprises, but its complexity and cost can overwhelm SMBs. Business Central ERP offers similar scalability with a manufacturing focus—like MRP and shop floor controls—at a fraction of the price.

Who Should Use Business Central ERP in Manufacturing?

Not every ERP fits every manufacturer. Here’s where Business Central ERP shines.

Perfect for Small to Mid-Sized Manufacturers

From custom furniture makers to automotive parts producers, Business Central ERP suits SMBs needing flexibility without enterprise-level overhead. Its cloud scalability grows with you—no rip-and-replace required.

Industries That Thrive with Business Central ERP

- Discrete Manufacturing: Think machinery or electronics—precise BOMs and production orders.

- Process Manufacturing: Food or chemicals—batch tracking and quality control.

- Mixed-Mode: Hybrid setups blending both styles.

Getting Started with Business Central ERP: Practical Next Steps

You’re sold on Business Central ERP—now what? Here’s how to take the plunge.

Explore Pricing and Licensing

Business Central ERP offers tiered plans—Essentials for core features, Premium for manufacturing extras. Costs start around $70/user/month (as of 2025), but consult a Microsoft partner for your exact needs.

Try Before You Buy

Sign up for a free Business Central ERP trial or request a demo. Test its manufacturing tools—create a dummy production order, track inventory, run a report. See how it fits your shop floor reality.

Connect with a Partner Today

A Microsoft Gold Partner can fast-track your Business Central ERP journey. They’ll handle setup, training, and support, ensuring you maximize ROI from day one.

Conclusion

Getting started with Business Central ERP is your ticket to a smarter, leaner manufacturing operation. From cutting production delays to mastering inventory, this cloud-based solution delivers the tools manufacturers need to thrive in a competitive world. With its affordability, scalability, and manufacturing-specific features, Business Central ERP isn’t just an upgrade—it’s a transformation.

So, what’s your next move? Have you explored Business Central ERP yet, or are legacy systems still holding you back? Drop your thoughts in the comments—I’d love to hear your story. Ready to see it in action? Sign up for a demo today and take control of your manufacturing future.